ENGINEERING CURVE AISI 1020 TABLE TEST CRACK

For designers, this is important in analyzing corrosion resistance, and fatigue crack initiation on components during their applications. The hardness of a material is the property that enables it to resist permanent plastic deformation, which is usually measured by indentation. After the process, the surface layers are deformed and hardened. Turning is a process whereby a single cutting edge is used to remove small chips of material from a rotating workpiece to create a cylindrical shape. Palabras clave: AISI 1020, ANOVA, velocidad de corte, profundidad de corte, velocidad de avance, dureza superficial, torneado. Finalmente, se propone una ecuación simple, para la predicción de los valores de dureza superficial, que representa los efectos de los parámetros del proceso. A partir de los resultados, se encontró que la velocidad de corte tiene el rol más importante en la producción de dureza superficial (69.2 %), seguido de la velocidad de avance (24.4 %), mientras que la profundidad de corte tiene el efecto menor (6.4 %). Se empleó un análisis de varianza (ANOVA) para determinar las contribuciones de cada parámetro estudiado en la variable de respuesta. Se demostró a partir de los resultados medidos que la dureza aumenta con el aumento en todos los parámetros. La influencia de varios parámetros de corte, velocidad de corte ( Vc), velocidad de avance ( f), y la profundidad de corte ( d) en la dureza superficial desarrollada por torneado en acero AISI 1020 recocido utilizando herramientas de insertos de carburo fue investigada. Keywords: AISI 1020, ANOVA, cutting speed, depth of cut, feed rate, surface hardness, turning. Finally, a simple equation is proposed, for the prediction of the values of surface hardness, which accounts for the effects of process parameters. From the results, it was found that cutting speed has the most significant role in producing surface hardness (69.2 %) followed by feed rate (24.4 %), while the depth of cut has the lesser effect (6.4%). An analysis of variance (ANOVA) was employed to determine the contributions of each parameter on the response variable. It was shown from the measured results that hardness increases with the increase in all the studied parameters. Not used in calculations.The influence of various cutting parameters, cutting speed ( Vc), feed rate ( f), and depth of cut ( d) on the surface hardness developed by turning annealed AISI 1020 steel using carbide insert tools was investigated. Transcribed image text: (a) Test Data Engr.

Show transcribed image text Expert Answer

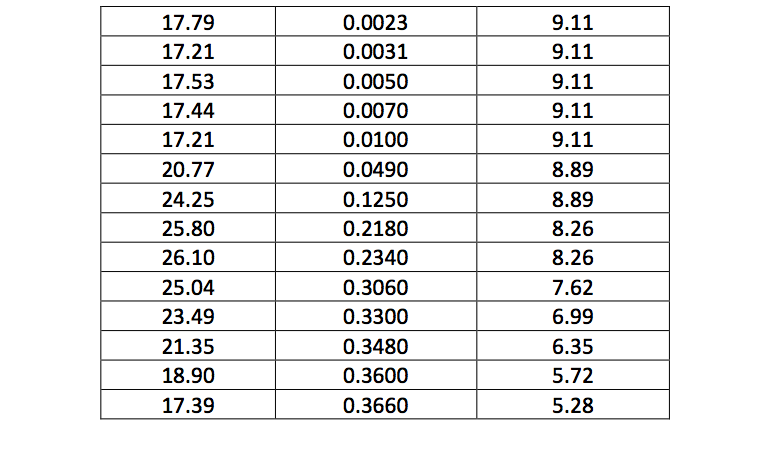

Table.Data and Analysis for a Tension Test on AISI 1020 Resulting stress–strain curve.Discuss the results. (d) Calculate corrected values of true stress, and plot the (c) Calculate true stresses and strains, and plot the true What would be the new length of the original 50.8mm Estimate theĮlastic strain recovered and the plasticstrain remaining. Ε = 0.0070, and thespecimen unloaded to zero force. (b) Assume that the test was interrupted upon reaching a strain Percent elongation, and percent reduction in area.Discuss the Modulus, 0.2% offset yield strength, ultimate tensile strength, (a)By plotting corresponding engineering stress-strainsĭiagram determinethe following materials properties: elastic (3) The final minimum diameter in thenecked region was 5.28 (2) Similarmarks originally 50.8mm apart were 70.9mmĪpart. Region were 38.6mm apart due to the lengthwise stretching in the Marks originally 25.4mm apart and on opposite sides of thenecked Were reassembled, and the followingmeasurements were made: (1) Measured manually with a micrometer in the necked region at Representative test data are given in Table (a) in the form ofįorce and engineering strain. Hot-rolled steel having an initial diameter of 9.11 mm. A tension test was conducted on a specimen of AISI 1020

0 kommentar(er)

0 kommentar(er)